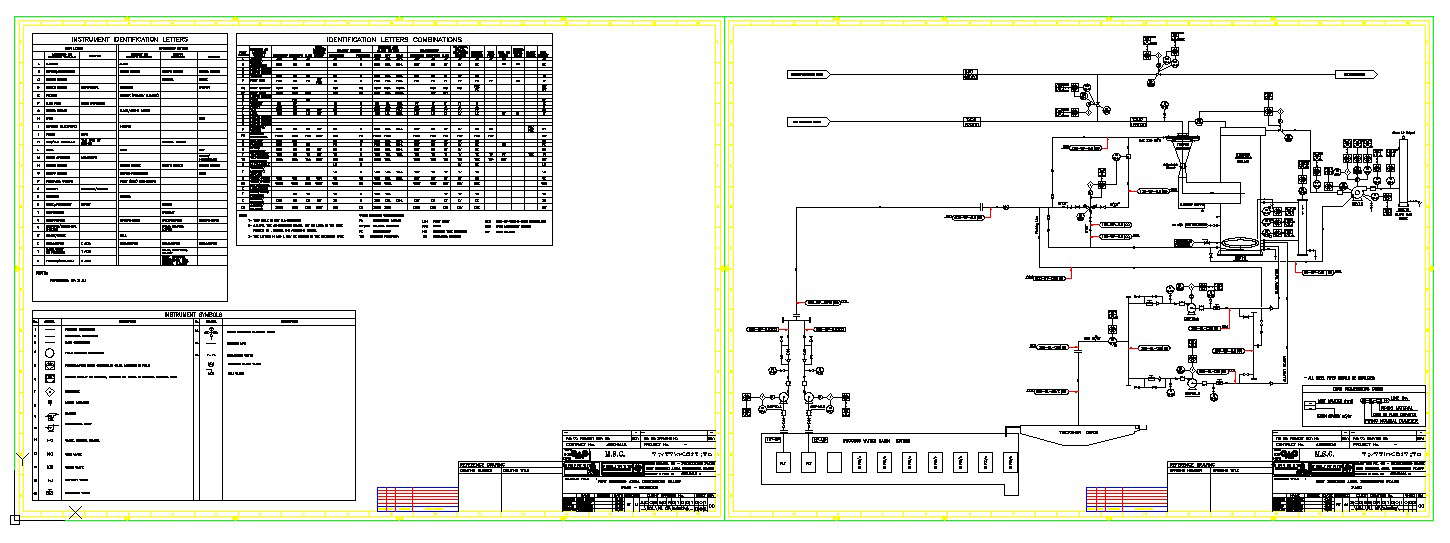

Venturi Scrubber P@id

Description

Venturi scrubbers are used widely for removing particles from gases because of their many attractive features: they remove sub-micrometer particles efficiently; they are compact and simple to build, so that initial investment costs are small in comparison to other types of particle collection devices; and they function well in problematic situations such as hot or corrosive atmospheres and when sticky particles must be collected.

A typical venturi scrubber consists of a converging section, throat section into which the scrubbing liquid is injected, and relatively longer diverging section where much of the energy recovery and particulate collection occurs. At the scrubber injection position, a high relative velocity between the scrubbing liquid and gas causes atomization of the liquid into a distribution of fine droplets. Impingement of gas upon a pool of liquid causes the atomization and entrainment of liquid drops. The predominant mechanism for particles greater than about 0.3 micron diameter has been shown to be inertial impaction.

In the last four decades, the technical community has expanded its responsibilities to society to include the environment, with particular emphasis on air pollution from industrial sources. One of the most common air pollution abatement devices used are venturi scrubbers (Figure 1). Such systems can be used either for the collection of particulate material from gas streams or for the control of Volatile Organic Compounds (VOCs). The advantages of these systems include high collection efficiencies for relatively small particles and low capital and maintenance costs. The main cost is associated with the operating fans that are used to overcome the venturi’s relatively high pressure drop (Naseh et al, 2006; Pulley, 1997; Silva et al, 2009).

A typical venturi scrubber consists of a converging section, throat section (Figure 2) into which the scrubbing liquid is injected, and relatively longer diverging section where much of the energy recovery and particulate collection occurs. At the scrubber injection position, a high relative velocity between the scrubbing liquid and gas causes atomization of the liquid into a distribution of fine droplets. Impingement of gas upon a pool of liquid can also cause the atomization and entrainment of liquid drops, and this principle is used in several types of commercial venturi scrubbers. Particulate matter is collected on liquid droplets by a number of collection mechanisms operating simultaneously. These include inertial impaction, interception, diffusion, condensation, humidification, and electrostatic precipitation (Table 1). However, the predominant mechanism for particles greater than about 0.3 micron diameter has been shown to be inertial impaction (Miller, et al, 1989; Rudnick et al, 1986; Wang et al, 2004; Yung et al, 1978).